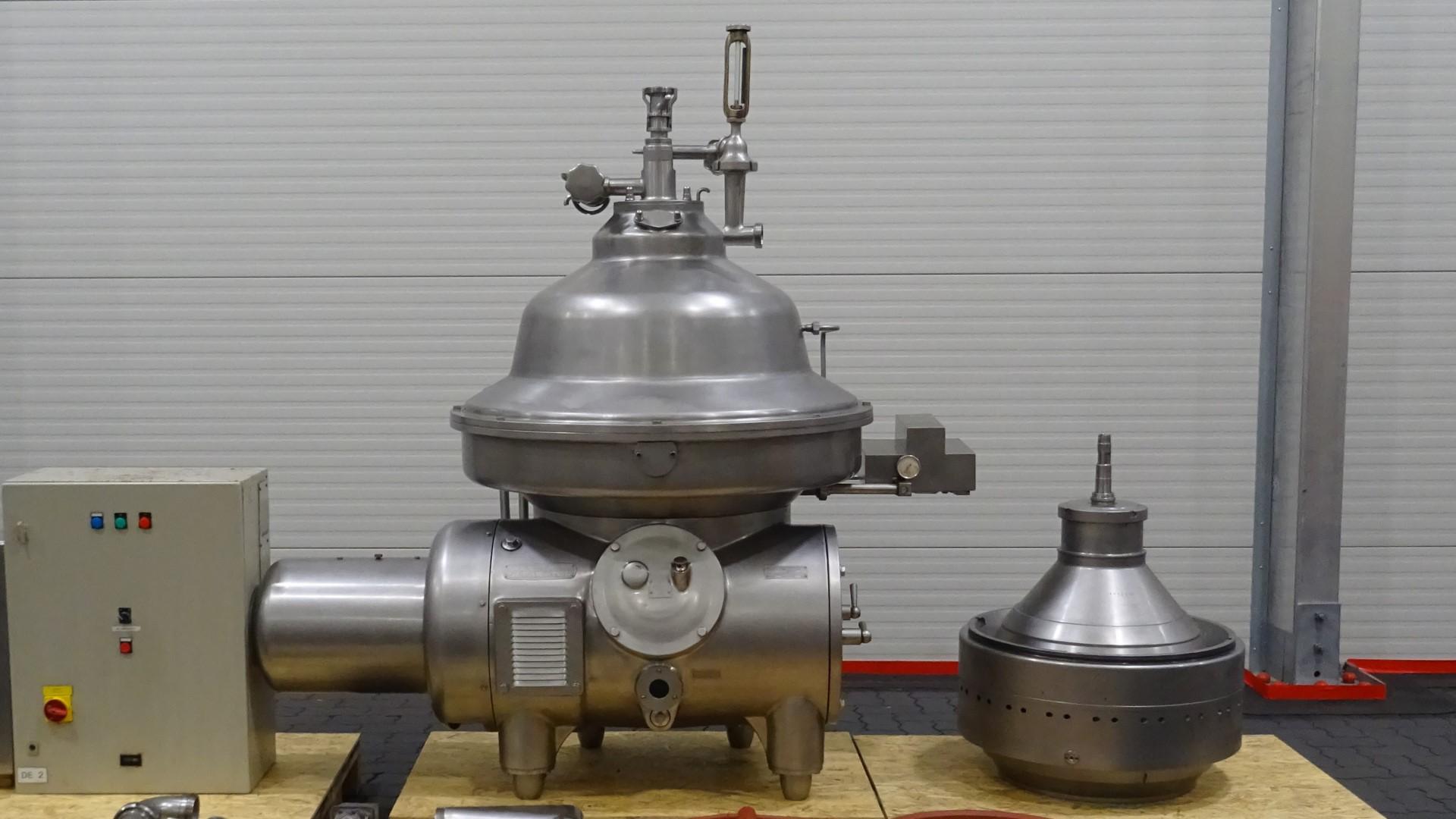

Milk Separators (Apv gaulin)

Achieve impeccable milk fat standardization and efficient bacterial clarification crucial for premium dairy products.

Our separators are built for **continuous, high-capacity industrial operation**, providing superior skim milk and cream quality. Featuring automated sludge discharge and advanced control systems, they minimize product loss and maximize efficiency.

Key Features:

- Capacities up to 5000/10000/15000/20000 LPH

- **High G-Force Design:** Ensures maximum separation efficiency up to 50,000 LPH.

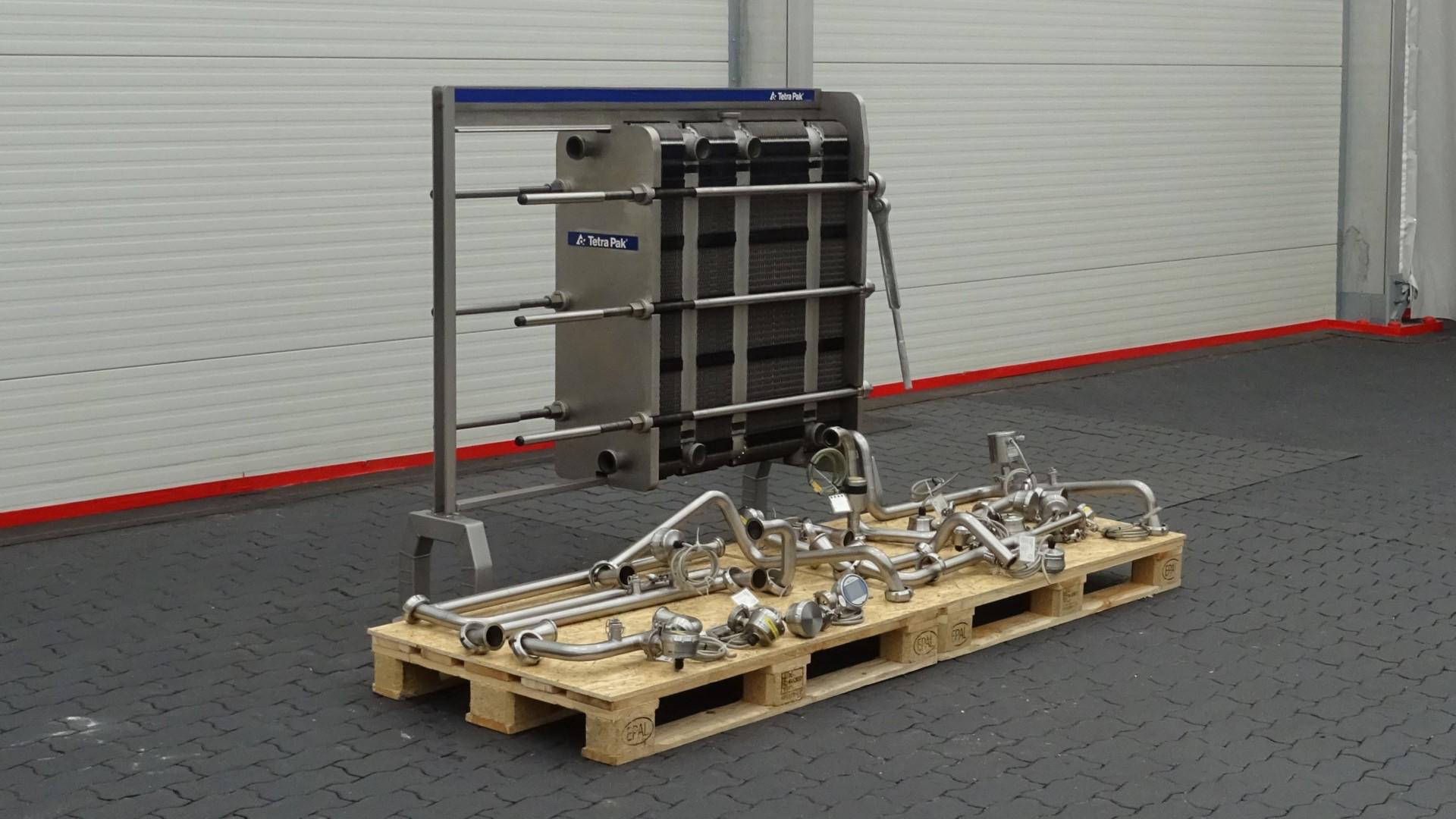

- **CIP Optimized:** Full integration with Clean-In-Place systems for rapid, thorough sanitation.

- **Energy Efficient:** Optimized motor and drive system reduces operational costs.